New Rapid Manufacturing Machine Stirs Hope

New hardware products in the additive fabrication industry are introduced with the unusual combination of fanfare and secrecy, and as a result, much skepticism. Too often, products ship many months late (eliciting vaporware accusations), then achieve performance or reliability levels that don't exactly match the initial marketing copy.

But hope springs eternal. And every once in a while, a product - usually from an established industry player - exceeds expectations.

|

|

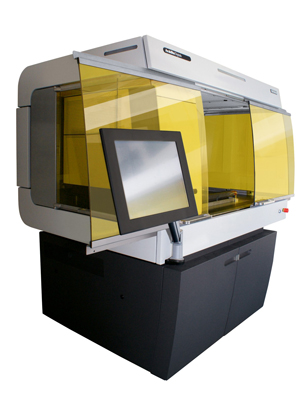

Industry experts say the Araldite Digitalis is an innovative machine. It uses micro-electro-mechanical system (MEMS) technology (the so-called MLS MicroLightSwitch) to distribute UV light in a controlled manner at a 90 degree illuminating angle, precisely exposing large areas (40,000 pixels) of radiation-curable resin at a time. "It always takes the same time to make a full sweep (exposure) which is clearly an advantage versus conventional laser exposure systems for which the total exposure time is depending on the complexity and the number of parts," says project leader Bernhard Sailer by email from Huntsman's facility in Basel, Switzerland.

This separation of processing time from the number and complexity of models to be built sounds the same as what is offered by envisionTEC's flash curing technology. It remains to be seen whether other claims of superior accuracy and reliability will push the Araldite Digitalis to the forefront.

Smartly, Huntsman has modest plans for 2009. It currently has one beta machine in Europe, with a limited rollout to follow. "Our plan is to enter the market in 2009 and sell a couple of machines," Sailer tells RapidToday. Pricing is "targeted" but being kept under wraps for now. Where the units will be manufactured is still undecided, says Sailer.

Even these modest plans may turn out to be over-ambitious, given the economy. In January, Huntsman announced plans to cut 9 percent of its global workforce in 2009, or 1,665 employees and contractors. This, while its stock price hovers around $3 USD, a 52-week low, and an 88 percent decrease from February 2008.

Recently, Huntsman has had a history of planned but failed mergers. In December, 2008, it received a $1B USD payment from Apollo Management, as part of a settlement deal the private equity firm agreed to after backing out of its $10.6B USD acquisition of Huntsman. This follows a $200M USD payment by Huntsman to Basell AF, after Huntsman backed out of a merger with the Dutch manufacturer when Apollo offered a sweeter deal.

In the meantime, Huntsman is working on developing more UV-curable resins that simulate thermoplastic properties for its new rapid manufacturing machine. Already developed is a transparent product.

Given the company's record in stereolithography resin development through its Swiss-based Ciba acquisition, expect swift progress. Huntsman recently announced a cool new SLA material - RenShape SL 7820 - that is a white photopolymer resin in its liquid state, turning jet black when cured.

Also in development is a next generation machine that expands the build envelope from the 650 x 370 x 600mm size of the current model. "The scaleability of this technology is another inherent advantage, so larger machines will be a logical next step," says Sailer.